CLIENT: Electronic Assistive Technology Company

INDUSTRY: Assistive Living

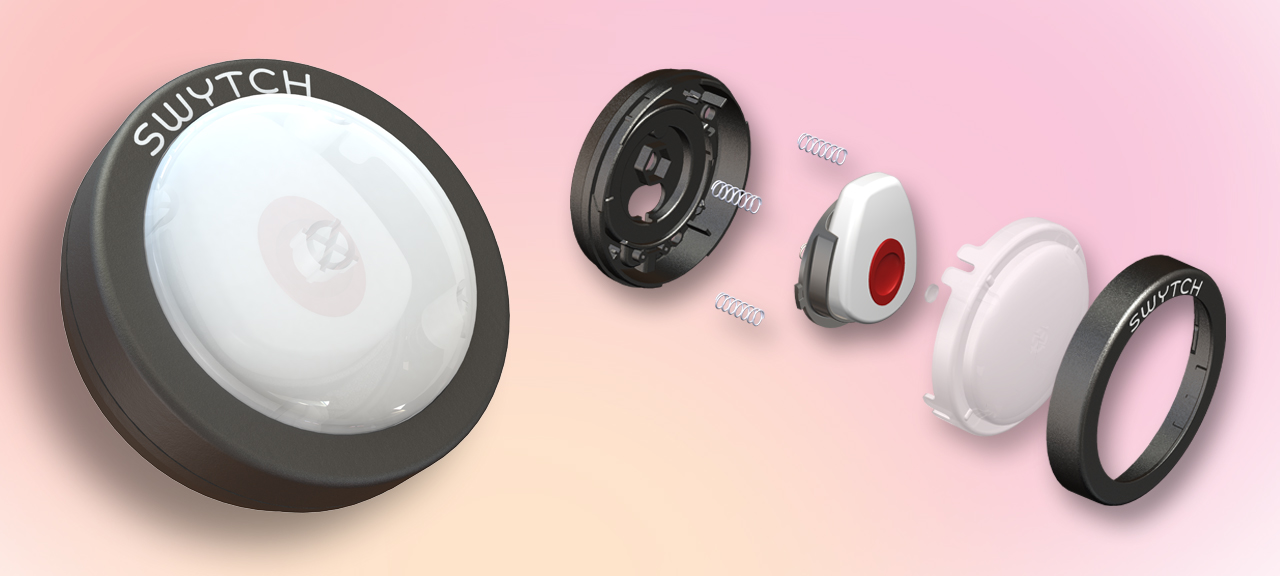

The client is considered a market leader in providing products to enhance quality of life for people with special needs. Sadly, there are many health conditions which are degenerative and care system equipment users may eventually find themselves unable to operate certain parts of their care system. Call buttons are a common element of these systems and are used to alert carers. Hillside Design was asked by the client to design a retrofit enclosure that would adapt several different wireless call buttons to large buttons to extend the service life of care systems.

A brainstorming session determined that it would be possible to design a universal housing with an internal mounting shoe accepting a range of carriers that were designed for each of the different wireless buttons. It was proposed that the universal enclosure would be injection moulded and the carriers would be initially manufactured using 3D printing to give greater flexibility while the true demand for the different types of wireless buttons was established. 3D printing also future proofs the product for use with other versions of wireless buttons as they become known.

Hillside Design made working prototypes to demonstrate the capabilities of the housing and prove its robustness in real life testing. With the design proven HPDL prepared a full suite of 3D and 2D data and then nominated a toolmaker/moulding company who they knew could deliver tooling and parts within the project timeline and at the level of quality the client required. HPDL supported the toolmaker during this stage and delivered mouldings right first time as promised.